موقعك الحالي:صفحة رئيسية>المنتجات

2017year8month11day Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche.

Read More

2017year7month13day Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim

Read More

2001year10month1day Abstract LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace

Read More

2001year10month1day LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag

Read More

1 天前 LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC. This supplements the existing Bim Son

Read More

2023year4month6day Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim

Read More

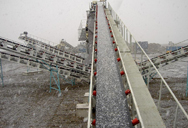

2017year8month12day • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above

Read More

The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical air-swept grinding mills dates back to Ernst Curt Loesche’s invention. In 1927, he applied

Read More

2023year7month31day In a VRM the grinding takes place by pressure and shear force. The clinker passes within seconds between roller and table. The energy input to the material during

Read More

1 ASTM (2019) ASTM C989-989M – Standard Specification for Slag Cement for Use in Concrete and Mortars. West Conshocken, USA: ASTM, 7p. 2 LYNCH, A (2015) Comminution Handbook. Southfield, USA: SME, 350p. 3 LOESCHE (2016) Loesche Mills For Cement and Granulated Blast Furnace Slag E 2016. Düsseldorf, Germany: Loesche,

Read More

2023year10month21day FOR SLAG CEMENT Granulated blast-furnace slag (GBFS or GBS) is a by-product of the steel industry. By water quenching of the molten iron slag a very dense and glassy product with an appearance like coarse sand is generated. Slag Cements are well recognised in many countries with traditional and powerful steel production. High

Read More

2012year3month1day Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements. From the energy aspect they are superior to grinding plant ...

Read More

2023year7month31day Granulated blast-furnace slag (GBFS or GBS) is a by-product of the steel industry. By water quenching of the molten iron slag a very dense and glassy product with an appearance like coarse sand is generated. Slag Cements are well-recognized in many countries with traditional and powerful steel production. High chemical resistance,

Read More

2001year10month1day Abstract. LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plants. Recent research has shown, that the application of these vertical roller

Read More

2013year4month11day Grinding of cement clinker and granulated blast furnace slag in roller grinding mills is a technology introduced by Loesche. VRM Re-Building Oasis Wear Tech Industries, Dubai Vertical Roller Millsl are a special grinding equipment, used by Cement Industry and Power

Read More

The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical air-swept grinding mills dates back to Ernst Curt Loesche’s invention. In 1927, he applied for a patent for the world’s first spring-loaded air-swept mill – the beginning of the triumph that is Loesche vertical roller mills.

Read More

Contribute to sbmboy/mn development by creating an account on GitHub.

Read More

Improvements in Cement grinding.pdf Ficem.clinker amp 90 130 kWh t cement in a modern plant,amp more for older.Difference between good amp poor mill operation amp maintenance can results in.system and VRM system from Cement International article about Loesche,page 65,2 2013Loesche Mills for Cement and Granulated Blast Furnace

Read More

1 天前 LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC. This supplements the existing Bim Son

Read More

2017year7month30day Loesche GmbH Hansaallee 243 40549 Düsseldorf, Germany Tel. +49-211-53 53-0 Fax. +49-211-53 53-500 Email: loesche@loesche Managing Director/CEO: Dr. Thomas Loesche Rüdiger Zerbe Amtsgericht Düsseldorf HRB 13611 loesche LOESCHE mill technology. In addition to the advanced technology and the

Read More

2003year1month1day The new MVR vertical roller mill for grinding cement raw material, cement and granulated blast furnace slag has a modular design, which enables operation to be continued even if one roller module ...

Read More

2023year4month6day Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC. This supplements the existing Bim Son cement plant in the province of Thanh Hóa, the total capacity of which has recently been increased to 4 million tons per year in ...

Read More

2018year6month12day The first LOESCHE LM 35.2+2 mill went into operation in Fos sur Mer in France in 1994. Just 10 years later (2004), a total of 50 plants of various sizes had been sold for the production of cement powder and granulated blast furnace slag. And in the next two years (until 2006), 50 more mills had been sold.

Read More

2001year10month1day A cement Vertical Roller Mill modeling based on the number of breakages. It is used to grind slag, nonmetallic ore, and other block and granular raw materials into the fine powders necessary for production. In the mid-1990s, Loesche GmbH developed the VRM technology, which was first used for grinding clinker and slag [3].

Read More

2018year6month8day Just 10 years later (2004), a total of 50 plants of various sizes had been sold for the production of cement powder and granulated blast furnace slag. And in the next two years (until 2006), 50 ...

Read More

2022year7month26day (granulated blast furnace slag, fly ash, pozzolanes, limestone etc.). The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press.

Read More

2018year1month1day Materials 2021, 14, 7869 2 of 17 granulated blast furnace slag and particle shape influence on the rheological properties was investigated and showed improved fluidity [8, 9, 25]. Additionally ...

Read More

2016year2month5day The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making. So far, very little work has been done to measure and quantify this impact. Yet for benchmarking, technology choice and general carbon optimization are important elements. The total slag production of a

Read More

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.